Description

Industrial enterprises place special demands on data transmission network equipment. Devices operate in extreme conditions, including wide temperature ranges, vibrations, electromagnetic interference, and the need for constant power supply. Furthermore, network failures in such environments, even for a few tens of milliseconds, can lead to accidents and billions in losses, which will ultimately outweigh the cost of a reliable switch.

For example, at oil and gas facilities, data on pressure and temperature in pipelines must be instantly transmitted to the monitoring system. If an alarm signal about a pressure spike is delayed even for a fraction of a second, the automation will not have time to react, and instead of a planned shutdown, an emergency relief or equipment damage will occur. Similar risks are characteristic of other industries: in mechanical engineering, a delay in data transfer from robotic manipulators leads to defects and line downtime, in the railway sector—to failures in traffic light and switch control, and in the energy sector—to disruptions in dispatcher control and mass blackouts.

The Eltex industrial switch series is designed with the requirements of the industrial segment in mind. We are systematically developing the lineup, regularly updating the software and expanding the model range.

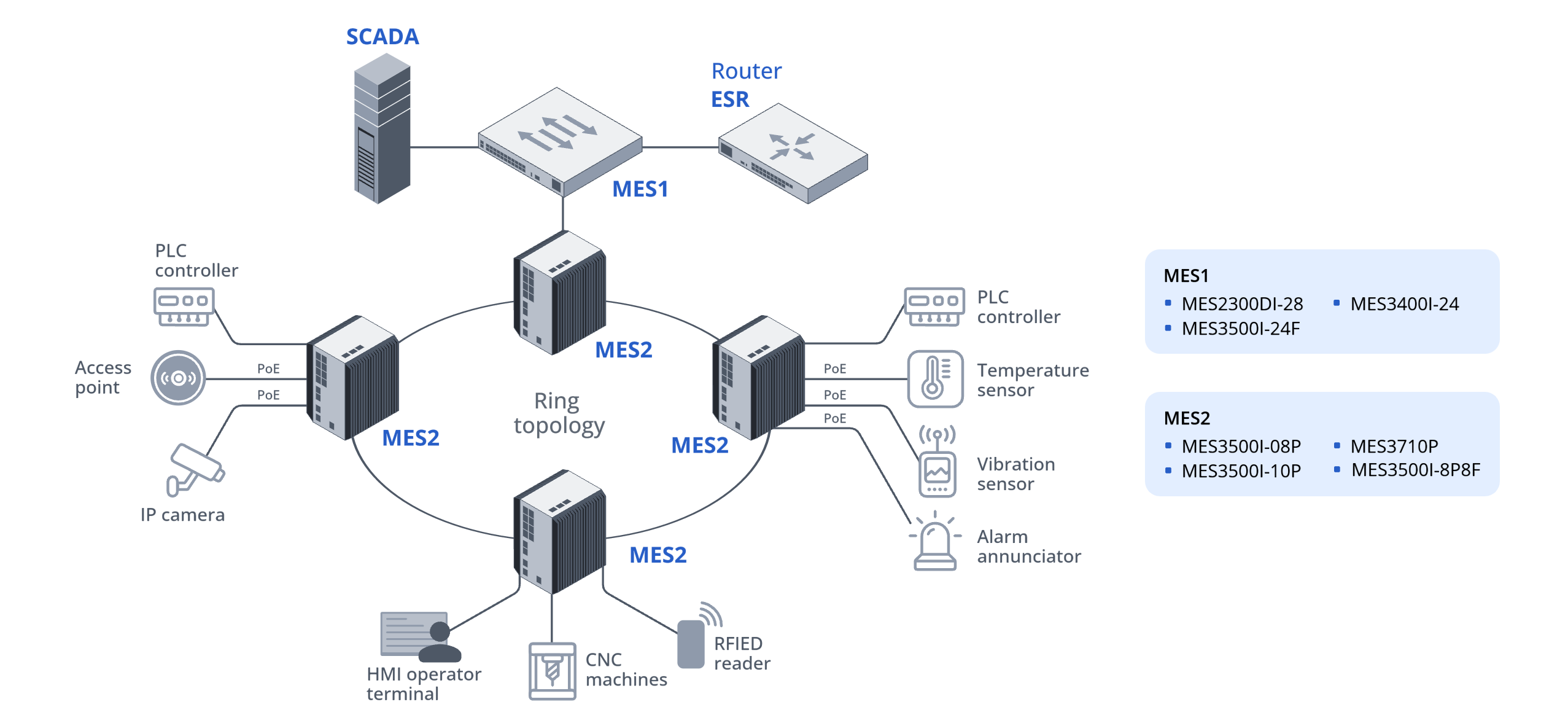

Solution architecture

The MES industrial switch series includes equipment for the edge level and the management level, as well as models with various port capacities, covering a wide range of tasks.

Management level models

All rack-mount switches support stacking of up to 8 devices. The equipment is fanless and uses a passive cooling system. Uninterrupted operation is supported by redundant, hot-swappable power supplies.

The devices are protected from external influences: they are vibration-resistant, dust-protected, shockproof with an IP30 protection class. The operating temperature range is from –40 to +60 °C. Operating humidity is no more than 80%.

Edge level models

Power is supplied by two DC sources. Operation from a 220 V AC is possible when an external DRS-270-56 power supply is connected. The equipment also features passive cooling.

DIN-rail mount switches also feature vibration resistance and dust protection. The protection class is IP30. The operating temperature range is from –40 to +70 °C, and the operating humidity is from 5 to 95%.

Advantages of MES industrial switches

When building a data transmission network at an industrial facility, it is important not only to provide basic data transfer but also to guarantee stable, secure, and predictable operation under all conditions. Eltex switches implement technologies that help build a fault-tolerant infrastructure and maintain reliable communication even in critical operating scenarios.

One of the features of the equipment is support for VRF (Virtual Routing and Forwarding) technology for MES35xx-xx and MES2300DI-28 switches. It allows the creation of several independent routing tables on one physical device, isolating various traffic flows. This prevents the influence of one type of traffic on others and helps avoid overloads and accidents.

The MES35xx-xx and MES2300DI-28 series support a set of L3 protocols. It is worth highlighting the PIM SM protocol, which enables multicast distribution. In the case of industrial sector networks, this is important, for example, for transmitting an alarm signal from one node to the others. Static IP routing and dynamic routing protocols (RIP, OSPF, BGP) are also supported.

Equipment management is carried out via CLI, SSH, Telnet, as well as through a web interface, which makes the configuration process more convenient.

Statistics collection and performance analysis are implemented via the SNMP protocol: it allows data to be obtained on CPU load, RAM usage, device temperature, and other key parameters. Users can obtain statistics for each interface, monitoring traffic using RMON and SMON protocols.

Development plans

The development of the MES industrial switch series continues in accordance with current market requirements. In the next two years, we plan to expand the model range and introduce new features.

Expected models:

- MES3500I-24F – Q3 2025 (interfaces – 20×1G SFP, 4×1G Combo, 4×10G SFP+; throughput up to 128 Gbps; power – 2 removable power modules)

- MES3500I-8P8F – Q3 2025 (interfaces – 8×1G PoE/PoE+, 8×1G SFP, 2×10G SFP+; throughput up to 72 Gbps; power: DC)

- MES3510S-08P – Q1 2026 (interfaces – 8×1G PoE/PoE+, 4×1G SFP; throughput up to 24 Gbps; power – DC)

- MES3510DS-24F – Q2 2026 (interfaces – 16×1G SFP, 8×1G Combo, 4×10G SFP+; throughput up to 128 Gbps; power – 2 removable power modules)

For the MES3510S-08P and MES3510DS-24F models, the implementation of the following protocols and technologies used for organizing data transmission networks at industrial facilities is underway:

- PTP (IEEE 1588v2) – for high-precision time synchronization between devices;

- SyncE – for transmission of a stable synchronization signal at the physical layer and increasing the accuracy of time synchronization via the PTP protocol;

- PRP and HSR – for ensuring data transmission channel redundancy without packet loss (with zero switching time) during failures. When using HSR, the MES3510S-08P switch can operate in the RedBox and QuadBox roles, which eliminates the need to search for additional equipment.